Functionality of a monitor system

The movable monitor system is also known as “XY-Rail” and “Driver Guidance System”.

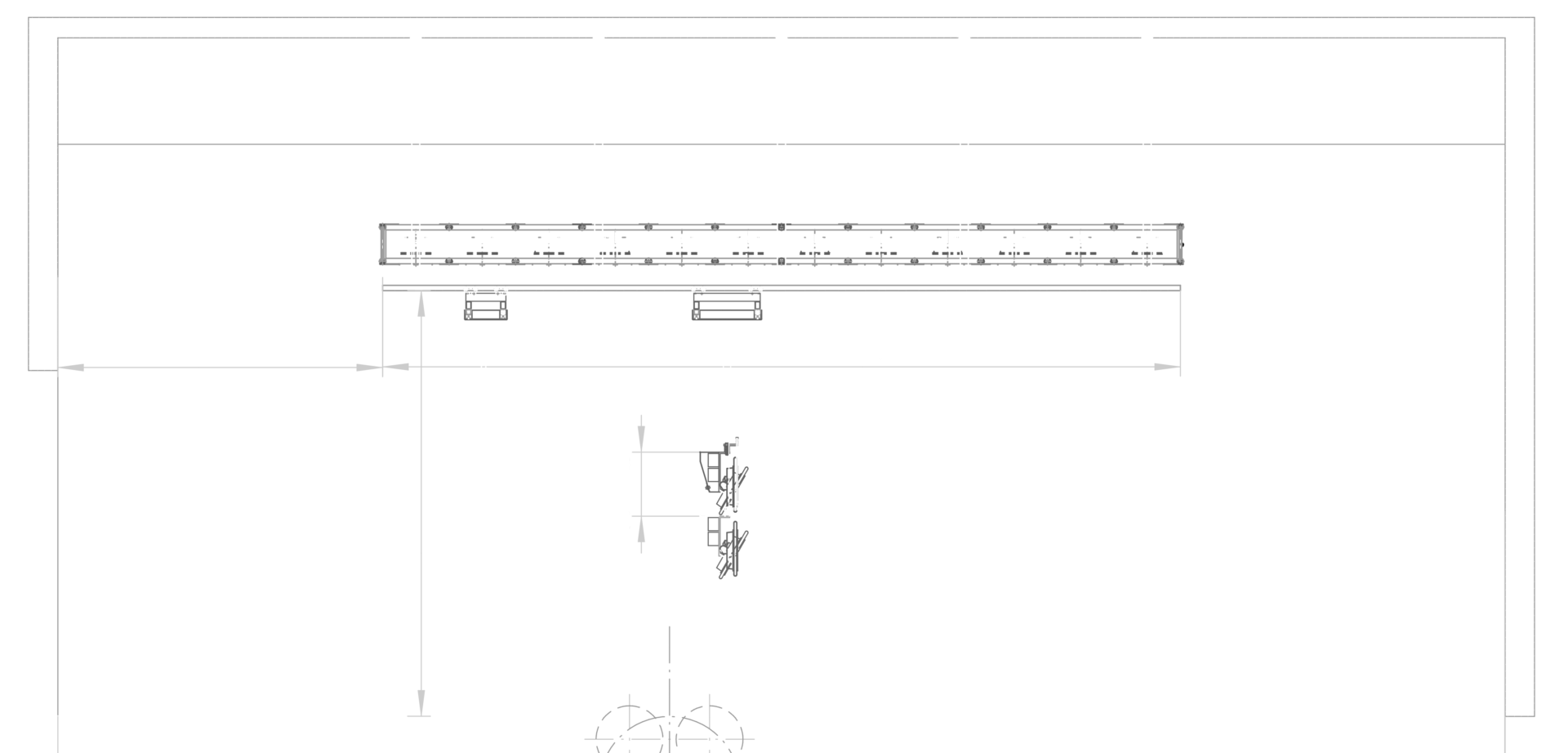

The movable monitor system displays driving cycles and measured values during a test run on a roller or flat belt test stand. For this purpose, a flat screen monitor and control units of the test stand are mounted on rails so that they can be moved in all three spatial directions. This makes the monitor system versatile for left- and right-hand drive as well as for different axle stands.

3D traversability

The monitor can be moved steplessly in all three spatial directions:

- Longitudinal slides (x-axis, front/rear)

- Cross slide (y-axis, right/left)

- Lifting linkage (z-axis, up/down)

Locations of operation

You can use the movable monitor system under very different conditions. Examples are:

- Roller and flat belt test benches

- Exhaust gas tests

- Performance and brake tests

- Endurance tests

- Outdoor test benches

- Climatic chambers (-40 °C to +60 °C)

- Acoustic test benches

Customizable

The following dimensions can be individually adapted to your test space and your requirements:

- Travel length: length of the longitudinal rails

- Travel width: length of cross rails

- Travel height of the lifting linkage

The monitor support is also designed according to your requirements. Determine the following components in the process:

- Monitor size and monitor format

- Housing for monitor (heated, cooled)

hanging devices for remote controls and emergency stop - Cable reel and 230 V connection

- Brake for x- and y-axis

- Option for later extensions (e.g. additional cables, remote controls, sun simulation)

Key Facts

- Purpose: Display of driving cycles and measured values during the test drive.

- Principle: Flat screen monitor and control units, can be moved anywhere in the room, can be expanded in many ways.

- Structure: longitudinal rails (x-axis, front/rear), cross slide (y-axis, right/left), lift linkage (z-axis, up/down)

- Test bench: roller test bench, exhaust gas test, endurance test, outdoor, acoustic test bench, belt test bench, climatic chamber -40 °C to +60 °C

Technical facts

- The monitor unit moves in a roller-bearing rail system and is easily movable.

- Lockable by compressed air driven cylinders

Electrically adjustable in height (self-locking) - Standard temperature range 10°C to 35°C

- Extension climate box with heating up to -20°C

- Extension heating collar for lifting column up to -40°C

- Extension cooling up to +60°C

- Optimal guided media supply by energy chains

- Flexibly expandable for measurement technology interfaces in the monitor area

- Expandable with additional slides for measurement technology

In use

The monitor carrier is kept at operating temperature by compressed air cooler or by heating.

Vehicle change

The uncomplicated three-dimensional mobility of the monitor system makes it possible to move the cross slide completely to the right, left or front. As a result, the test vehicle’s travel path is free and it can be quickly exchanged for another vehicle.

This easy-to-handle vehicle exchange procedure is already planned for when dimensioning the travel width.

Inspection

You are welcome to arrange a regular inspection of the entire monitor system. This way you avoid unnecessary downtime of your test operation. The maintenance is carried out by S. Bleyer GmbH.